After the previous post, many industry friends contacted us to discuss plugging details; for a long time I have wanted to write a thorough article on raw-coal-bunker plugging, and this is the chance to give a simple analysis grounded in practical experience.

Having worked more than ten years on anti-plugging retrofits for power-plant raw-coal bunkers, having dealt with fuels of all kinds both at home and abroad, and having seen every kind of anti-plugging measure, I have formed my own understanding and definition of how bunker plugging arises.

Here I set out the principles of the various anti-plugging technologies now on the market, so the industry can better understand and solve the problem.

Coal-bunker plugging is a fairly common phenomenon in daily plant operation; from grassroots workers to plant managers everyone can give a rough explanation, and anti-plugging vendors each have a self-consistent theory.Based on my own visits to more than a hundred plants and my attendance at technical forums, it is clear that this seemingly common phenomenon still lacks a true scientific theory.To solve bunker plugging once and for all, we must have a correct analysis of its mechanism—using kinematics, mechanics and certain mathematical models to help us understand it.

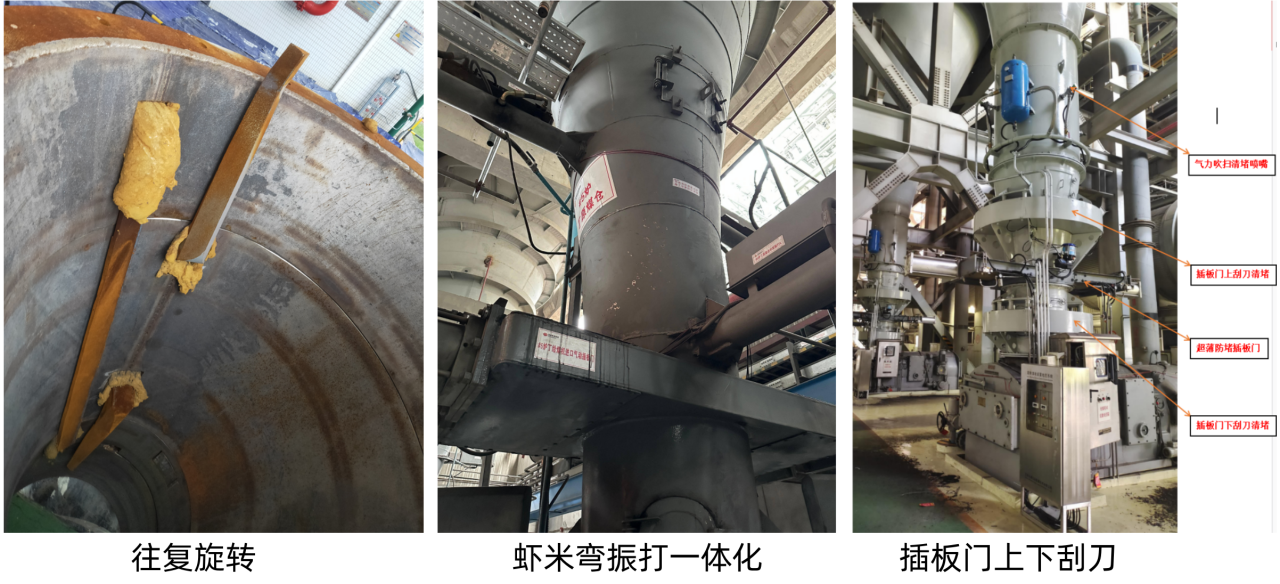

Of the dozen or so anti-plugging vendors, only the “shrimp-bend air-hammer vibration integrated device” cites any scientific theory; according to available material it draws on concepts from granular-flow mechanics, so I will use its analysis as a starting point for a preliminary study of coal-flow behaviour inside the bunker.

Does the flow of coal in a bunker really conform to fluid-mechanics or to granular-discrete models?Before explaining those models, I believe we must divide the bunker-feeder system into two boundary conditions: first, the bunker outlet opens into an infinitely large container (no feeder)—we call this free gravity flow; second, the outlet is connected to a feeder—we call this mechanically forced flow.

A. Does bunker coal flow conform to fluid-mechanics concepts?

Under the first boundary condition—free gravity flow—fluid-mechanics concepts can be used only partly; there are marked differences and limitations, analysed below:

Similarities: partial conformity to fluid-mechanics traits

Continuity: under ideal conditions (uniform fineness, proper moisture) the flow can be treated as a continuum, resembling a viscous (non-Newtonian) fluid.

Gravity-driven flow: coal flows under gravity like a fluid in a vessel, and Bernoulli’s equation can be used for simplified analysis.

Pressure distribution: pressure at the bunker base rises with height, similar to hydrostatic pressure (but the internal friction angle of coal must be considered).

Differences: non-typical fluid behaviour

Granular nature: coal is an assembly of discrete solid particles with internal friction and shear resistance, violating the inviscid assumption of ideal fluids.

Non-Newtonian behaviour: coal flow may show shear-thinning or blocking (arching); powder or granular mechanics are needed.

Air permeation: interstitial air flow influences the bulk, requiring permeability parameters.

Key influencing factors

Physical properties of coal: size distribution, moisture and stickiness (e.g. lignite) strongly change flow characteristics.

Bunker geometry: cone angle and outlet size must be designed to prevent arching.

External conditions: vibrators or air blasters improve flow but are outside classical fluid mechanics.

B. Does bunker coal flow conform to granular-discrete models?

Under the first boundary condition—free gravity flow—granular-discrete models can be applied:

Rigid boundaries: fixed geometry—conical, square or hyperbolic bunkers; different friction and restitution coefficients can be set.

Periodic boundaries: simulate an infinite system, suited for studying bulk behaviour.

Free-surface boundaries: interface with air or another medium, normally unconfined.

In summary, under the first boundary condition coal flow is poorly suited to either fluid-mechanics or granular-discrete simplifications; moreover, actual plant bunkers operate under the second boundary condition where the feeder imposes an additional constraint, clearly violating classical granular-discrete assumptions.

Mechanically forced flow is far more complex; neither fluid mechanics nor granular-discrete theory can be applied directly; traditional fluid mechanics would require numerous correction parameters and still could not cover all special behaviours.Engineering design therefore relies heavily on experimental data and semi-empirical formulas.Present bunker design uses granular-discrete models to optimize wall angles for different coals under varying moisture and size distributions, but it does not account for the mechanically forced flow imposed by the feeder; feeder rate fluctuates with boiler load, making boundary correction difficult.

Based on the above, I believe plugging is closely related to the mechanically forced flow from the feeder; coal type and bunker structure contribute, but more directly, the flow-rate difference ΔQ = Q_gravity − Q_actual between the gravity flow from the bunker and the actual feeder rate is the core cause of plugging at the feeder inlet.This imbalance causes accumulation, compaction and finally arching; mechanism, influencing factors and solutions must be examined.

Mechanism of plugging caused by flow-rate difference

Dynamic imbalance process

When Q_gravity > Q_actual: bunker flow velocity > feeder take-away velocity → coal piles at feeder inlet → pile compacts → internal friction rises → flowability lost → plugging.

When Q_gravity < Q_actual: feeder “empties” local coal → cavity forms → flow from above interrupted (rat-hole) → feeder starved → later collapse of compacted mass causes sudden impact plugging.

In many plants I often hear: “The feeder inlet itself isn’t blocked; the lower drop pipe is empty; it’s the upper bunker that won’t discharge.”This is an illusion; arching in the upper bunker is in fact the extension of lower plugging, the result described above.

Critical plugging triggers

Compaction layer: accumulated coal loses porosity and permeability, forming a dense layer (akin to soil hardpan).

Shear resistance rises sharply: internal friction angle exceeds the angle of repose (>50°), reaching the yield-stress limit; flowability falls to zero.

Gas-solid coupling: air entrained in fine coal is compressed and then escapes, locking the mass.